- TOP \dsc-sys\inv_client_edit.php

- Business Summary

- How the aluminum product is created

MA Aluminum can manufacture a wide variety of materials from aluminum ingot. Technical expertise cultivated by being a fully integrated rolling company is what makes keeping high quality possible.

Sheet Process

Sheet/plate materials are manufactured by rolling. It is a processing method to turn a pair of rolls placed in parallel to make a cuboid slab (ingot) travel in between for thinning. The slab will be extended towards its travelling direction to become thinner to the designated thickness. It also transforms the slab into that with higher uniformity and quality by destroying alloy structure.

Process Chart

Foil Process

A foil will be manufactured by rolling the sheet (take-up product) even thinner. A very thin foil will be rolled by using two sheets (doubling).

Process Chart

Extrusion Process

Extrusion processing is a method of extruding aluminum and aluminum alloy at temperatures between 400°C and 500°C. A cylindrical ingot (billet) is placed on a die attached to an extruder and is subjected to strong pressure to obtain a long product with the same cross section (the extruded material). Through this process, hollow or complex cross-sectional shapes that are difficult to manufacture using other processing techniques can be easily created through a single extrusion process. This approach also enables the creation of products with high dimensional accuracy.

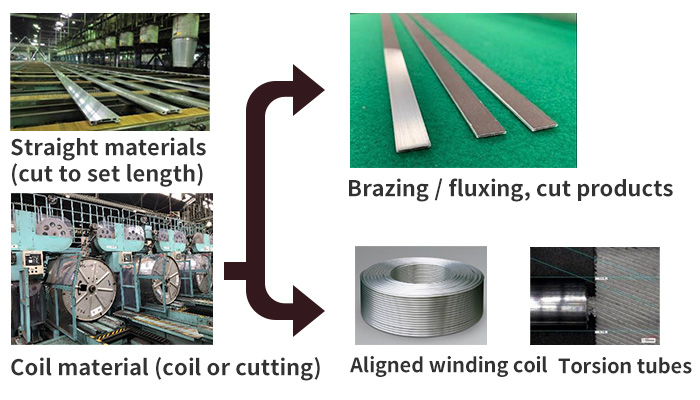

The extruded products are manufactured as products cut to designated lengths and rolled products.

With products for heat exchangers, zinc spraying, brazing, fluxing, twisting (round pipe) and other processes can be added upon request.

Process Chart

Finished Product Shapes